It’s an unfortunate fact of life that salt water and boat trailer brakes really do not mix, so keeping your trailer brakes in top working order should always be a priority. In this article we will cover the different types of trailer brakes and give you a few tips on how to keep them working properly.

In a nutshell you have three types of trailers as far as trailer brakes go.

Un-braked, which is pretty self explanatory.

Over-ride brakes, which is the system where the tow coupling slides inside the hitch to operate either a mechanical or hydraulic system to apply the brakes.

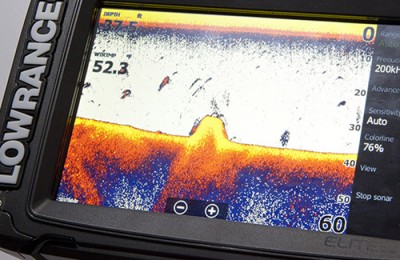

Electric over hydraulic set up, where an electronic control module applies power to a hydraulic brake actuator. Electric over hydraulic systems also have an in-car controller. This allows the trailer brakes to be operated independently of the car brakes.

Electric over hydraulic trailer brake system. The black box contains the battery and the silver box contains the hydraulics. It is important to keep the battery charged and brake fluid topped up regularly in order for the system to work correctly.

When working correctly, over-ride and electric over hydraulic systems are extremely effective in stopping the car and trailer in both an emergency and in normal driving conditions. However, with little or no maintenance, boat trailer brakes will succumb to the constant exposure to salt water and will become inoperative.

There are options out there to combat the salt degradation, such as stainless steel brake callipers and rotors. These work extremely well, however as you can imagine they are not cheap.

By far the easiest option is to correctly maintain your brakes to ensure they do not deteriorate and become inoperable. Like most things in boating, the less you use them, the more they are likely to deteriorate.

With over ride brakes, everything is pretty simple. Whether they are cable or hydraulic, there are a few things you need to do to ensure they stay in good working order. The first and easiest part is keeping the sliding hitch actuator lubricated. This is done by simply pumping grease into the grease nipple on the side of the hitch receiver. Doing this once or twice a year is probably adequate. Some service centres include this in their motor service. Check the actuator regularly and if it is looking a bit dry, be sure to add some more grease.

The next thing to check is the brake lock tab. When reversing up a hill or over rough ground or a kerb, the brake lock tab flips over to render the brakes inoperative so that the reversing can be carried out easily. Without the brake lock tab, the rearward motion would cause the sliding hitch to apply the brakes. The brake lock tab can easily become corroded and seize in the ‘brakes off’ position, so to avoid this dangerous situation, simply lubricate the brake lock tab regularly with a lubricant such as CRC.

Located at the wheel end of these systems is either a hydraulic brake caliper or a lever and cable system attached to the brake calliper. Inside the brake calliper, whether hydraulic or cable, there should be brake pads. Trailer brake pads are cheap and relatively easy to replace so keep an eye on them and be sure they are in good shape. If in doubt just replace them.

The other issue that can often arise in seldom used trailers is the calipers seizing. This is probably a bit more common in the hydraulic type but will also happen to cable types as well. If you are checking your callipers regularly and find the problem early enough, simply pulling the caliper off, working the hydraulic piston in and out with a G clamp and applying the brakes can quite often get the brakes working again. Applying CRC Penetrate and letting it sit for a day or two may also help in getting the piston moving again. Unfortunately, unless you discover this issue early, more often than not the only remedy is to replace the caliper.

These are hydraulic over ride trailer brakes. You can see this one is missing the brake fluid reservoir cap which means the brake fluid will be severely degraded and not do its job. The brake lock out tab is engaged and probably lives in this position. This trailer is a danger to other road users.

If you have a cable activated override brake system, keep in mind that the cable will need to be adjusted occasionally. This can be due to a bit of stretch in the cable and also due to the brake pads wearing down. On some occasions you may also find it necessary to slacken the cable slightly after replacing the brake pads.

With hydraulic systems, bear in mind that brake fluid does not last forever. Brake fluid by nature absorbs moisture which reduces its ability to do its job, so it is important to bleed and replace hydraulic brake fluid yearly. It is also a good idea to test the breakaway system on a semi regular basis. Electric over hydraulic brakes should always be operable whenever you are driving. Towing a load that is heavier than your car without brakes is very dangerous. If you are unsure of how to service your own brakes, it’s better and safer to give the job to a professional.

Batteries Part 1 – 12v, 24v and 36v

Don’t miss our three part series on batteries! Find out all you need to know about battery linking, charging your batteries and choosing the right battery for the job. Check out Part 1 here.

DIY Trailer Wheel Bearing Replacement

With the right tools, replacing your trailer wheel bearings is easy. Check out our step by step guide here.

Important Tip

Keeping an eye on the condition of your brakes and carrying out regular maintenance will ensure your brakes are always in top working order. It is a good idea to get into the habit of checking your trailer brakes after a day out fishing while the boat is not on the trailer. Before you bring the trailer down to the boat ramp, have a quick look at the brake rotors to ensure that there is even wear showing on both sides of the rotors and on all wheels. Uneven wear patterns or wear on the rotors will be your first sign of any issues. Trailer brakes will not last forever and will need replacing at some stage, however washing the brakes well with fresh water after every use will see them lasting much longer.